Thin Client Conversion

The Challenge:

Converting a Large Multi-node PC-based HMI System to a Terminal Services Thin Client System

The client, a global manufacturer of household products, asked MidStates to convert a large PC-based (thick client) HMI system to a terminal services Thin Client system. The HMI PCs were near the end of their operating system lifecycle and were due for an upgrade. The existing system required many hours of maintenance per year to apply security patches and updates. In the event of a hardware failure, recovery time took hours.

Rather than invest in new PCs, the client decided to utilize company IT resources to provide virtual terminal servers to run the HMI applications and use Thin Clients for the HMIs on the plant floor. The new system would require considerably less maintenance and would greatly reduce recovery time for a hardware failure.

The Existing System:

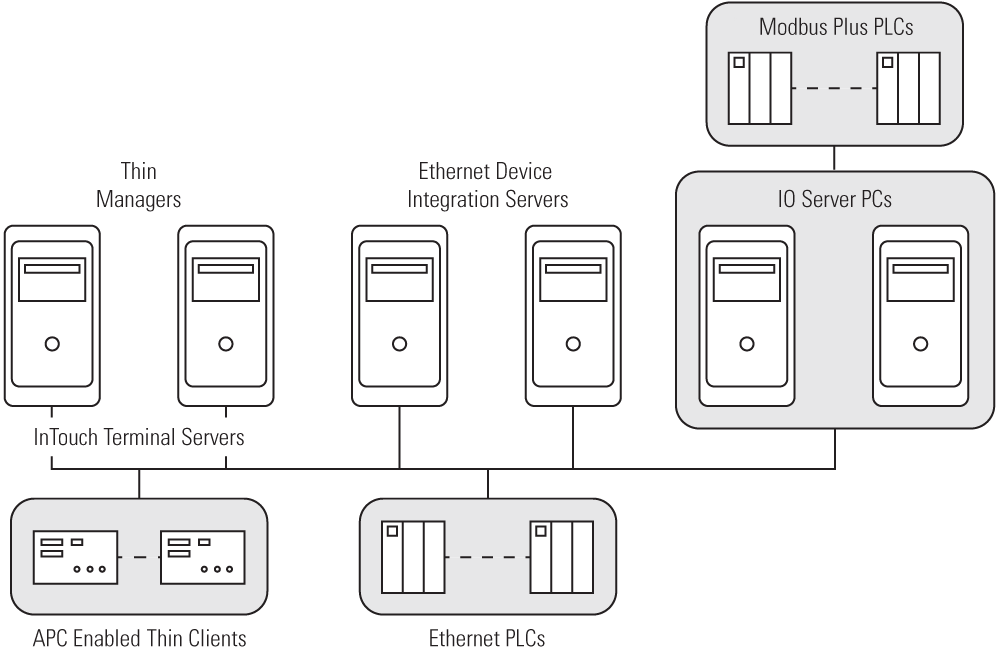

The existing system consisted of 43 stand-alone Wonderware InTouch nodes across multiple production areas. The majority of the HMI applications were unique. Each node was running its own device integration and/or legacy IO server to communicate to the plant PLCs. There were a total of 31 PLCs requiring Ethernet communication and 25 PLCs requiring Modbus Plus communication. The PLCs were a mix of Modicon and Allen-Bradley.

Initial Engineering:

First, we evaluated the HMI applications in each area for similarities and combined them where possible. We tested any HMI application that used an add-on script or custom software on a development terminal server to ensure that this functionality was compatible in a terminal services environment. We determined that two terminal servers would be required to handle the 43 InTouch sessions.

Next, we documented all communication to PLCs to determine the number of device integration servers and Modbus Plus IO servers needed to avoid multiplexing overloads. The communication load required two virtual servers running Modicon and Allen-Bradley Ethernet device integration servers and five Modbus Plus IO server PCs . The Modbus Plus IO servers are classified as PCs because of the physical connection to the network through a communication card.

A labeling standard was defined for each Thin Client, containing all of the information a technician would need to replace a failed terminal without having to rely on other documentation.

Startup – Phase I:

The Ethernet device integration servers and Modbus Plus IO servers were set up and installed. Then, we modified the existing HMI applications to connect to the PLCs through the new servers instead of directly, as in the past. This identified any communication bottlenecks.

Startup – Phase II:

We set up terminal server users, InTouch software, and ACP ThinManager. Next, we converted InTouch applications to run in a terminal services environment and tested these via RDP sessions. We configured the ACP Thin Manager software in a redundant configuration across both terminal servers. Then, we logged in all Thin Client terminals and verified that they logged in as correct users and were running the correct HMI application. This phase verified that the configuration was complete and functioned properly, without having to shut down the existing system.

Startup – Phase III:

We worked with the plant personnel and switched the hardware during process lulls. The existing 43 PCs were replaced with Thin Client terminals over a number of days. This did not require or cause any production downtime. Terminal-to-terminal shadowing was implemented to reduce or eliminate travel by operators between areas to monitor equipment.

Post-startup – System Maintenance:

The plant IT organization provided two sets of virtual servers: one set for production, and the other set for testing. (When new security patches or software updates are released, they are first installed and tested on the test servers.) We provided a set of instructions that the plant technicians use to validate the functionality of the HMI applications after the installation of patches. This provides an opportunity to identify and resolve any issues before the patches were installed on the production servers.

How may we help you improve your operation? To discuss your challenge or conversion plans, please contact MidStates Controls.

(262) 554-6660

(262) 554-6660